What is HRC Steel Ratings: Rockwell Hardness Scale

|

|

Time to read 4 min

|

|

Time to read 4 min

Straight razors can be divided into two parts, the handle, and the blade. Of course, there are other parts of the straight razor, which you need to focus on to understand its full mechanism. But for now, the star of the show is the straight razor’s blade.

A straight razor will lose its primary function without its cutting edge. Hence, it is crucial to know the quality of the steel used in making a straight razor blade. For that reason, experts use the Rockwell Hardness C-Scale (HRC) to measure and rate your blade’s hardness.

Here's what you'll find in this article:

Rockwell Hardness is not a unit of measurement but rather a test. It is a series of quality examinations made to know how resistant steel is to other materials. This is vital in ensuring that your blade is strong enough to perform its primary function. Can you imagine your straight razor’s blade breaking or chipping off as soon as you use it? Unacceptable, right?

There was no definite and universal way to test the hardness of steel until Hugh M. Rockwell and Stanley P. Rockwell came up with the Rockwell Hardness tests. These partners, who are surprisingly not closely related, literally revolutionized the history of mechanical testing.

Stanley Rockwell was the first to patent the idea of testing metals in 1914. It was with Hugh Rockwell’s help that brought the concept to life in 1919. The process is simple: an indenter is pushed into the metal, wherein the difference between the depth of indentation and the initial depth under preliminary force determines the hardness of the material.

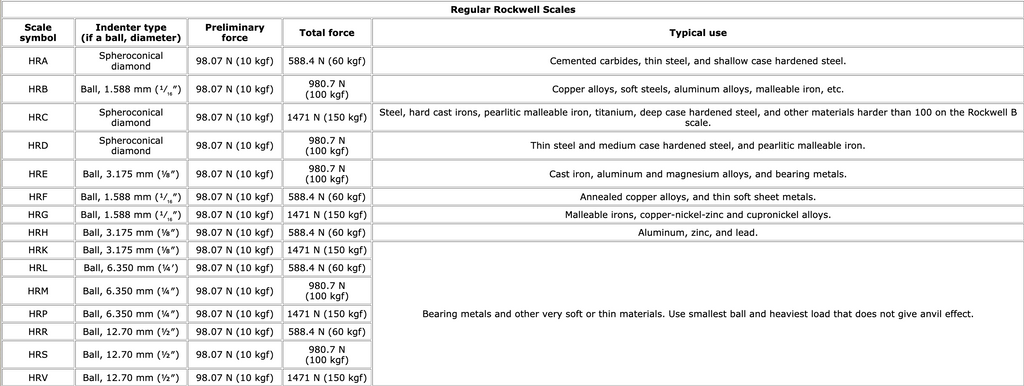

This test uses different materials for the indenter. Hence, the varying scales ranging from A-V. For straight razors, we use HRC, which is again the c-scale of Rockwell Hardness.

An HRC test is done by utilizing a spheroconical diamond as an indenter while enforcing a preliminary force of 10kgf and a total force of 150 kgf. Straight razor manufacturers do the HRC steel test because it is the definitive metallurgical test for hardened steel like straight razors.

Meanwhile, you can check out this Rockwell scale chart to know the other kinds of materials and force is used for different types of metal

What is this rating, and what number can you consider a "good" HRC rating for hardness? That is what you are wondering—yes?

When discussing how hard something is, it can be difficult to be precise about it unless you have a measurement.

If you were to imagine something is as soft as jello, for instance, you would have a good idea of the consistency and softness. But that softness would depend on if it is a cold day or if the jello is fresh out of the refrigerator.

But when it comes to steel, you might think that hardness is about how strong and durable it is. Suppose a blade easily breaks with a minute force, you will say that, yes—it is brittle, it is not hard. But is that blade soft? Obviously, it is hard.

Determining the hardness of steel is not easy. It does not have a black or white answer. Instead, it is determined by different factors, not just its stiffness, durability, and brittleness. And, again, that is why straight razors are rated through HRC.

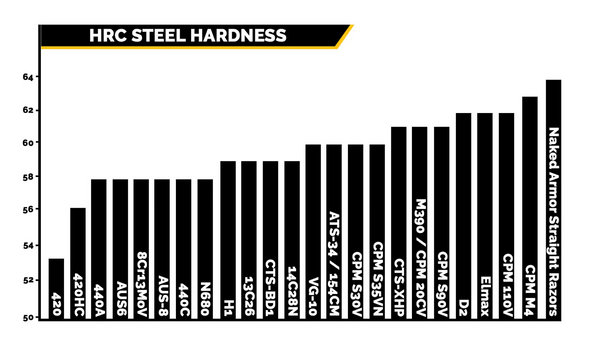

For those looking for excellent straight razors, the best ones in the market have ratings from 60-66 HRC. To have a clearer idea of how hard it is, let us just say it is harder than an ax, which would be about 50 HRC, and special knives found in the supermarket, which are about 54-58 HRC

A 60-66 HRC steel rating is suitable for straight razors because the higher ratings make for a thinner cutting edge. This guarantees that your straight razor is built to be sharper.

Naked Armor’s straight razors fall under this ideal rating. Hence, you can rest assured that it is sharp enough to bite through your hair, giving you a closer and cleaner shave. These razors are also strong enough to last you a lifetime, especially if you put effort into maintaining them.

We make sure that every straight razor is expertly crafted with care and following the right protocols. If not, what is the point of producing straight razors if the blade cannot serve its purpose? And we use highly-acclaimed steel for our materials, which you can enjoy if you get our Solomon Straight Razor with a 61-65 HRC Japanese steel blade.

The short, easy version is that HRC steel ratings measure how much of a mark or dent a diamond point can make in the metal with a measured amount of weight. The smaller the mark, the harder the steel. The higher the rating, the harder the material, so the finer the cutting edge can be.

Remember that every metal has strength and hardness. However, when we use it for industrial applications, like cutting softer materials like hair, it will eventually get damaged. Therefore, it is recommended for you to choose a straight razor with at least a 60 HRC rating to ensure that you will have a long-lasting grooming companion like any of our straight razors here at Naked Armor.

When you have top-quality blades, you do not have to worry much about maintenance. Of course, it will still be necessary to strop your straight razor every time before you shave. Even the best blades give up without proper care. But, we guarantee that following this guideline for blade hardness will lessen the need to hone your razor.